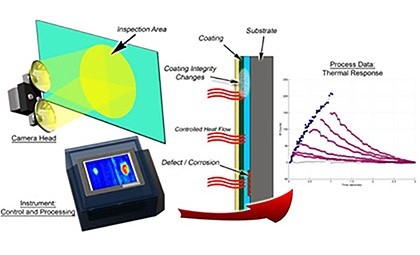

A version of the IR-CIS instrument is available for measusrement of coatings in a shop

during fabrication. There are no quantitative nondestructive coating assessment methods available

for use in a fabrication shop.

Coatings are primarily assessed visually. Currently, the most quantitative

measurement is typically of thickness and records are kept by hand, on paper.

The lack of quantitative measurements can result in coating failures that are not identified

in the shop, where they can be more easily repaired. The lack of a permanent measurement record

and a traceable written record can make assessment of failures that may occur later in time in

the field more difficult.

|

Applications

- Indoor measurements

- Outdoor measurements

- Measure all girders

- Measure webs, flanges, stiffeners, other components

|

|

|

|

Key Features

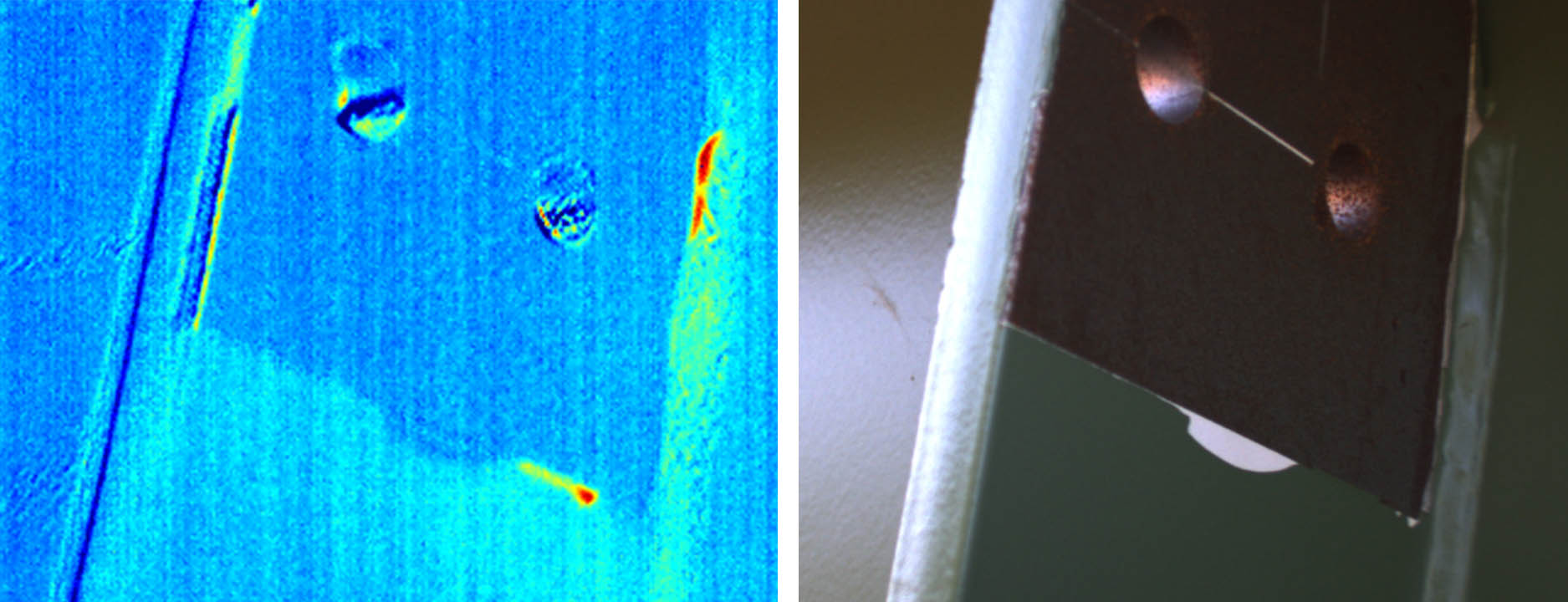

- Objective, quantitative results

- Near real-time analysis

- Easy to interpret images

- Highly reproducible

- Portable, Hand-held device

- Simple to operate

- Automated data collection and analysis

- Option for integrated with mobile platform

- Minimal impact on operation

- Non-contact measurements from large distances

- No traffic control required

- Environmental tolerance

- Suitable for field environments

- On-board ships and offshore structures

- Manufacturing facilities

|

Measurements

- Loss of adhesion

- Debonding, delamination and blisters

- Cracking

- Corrosion under coatings

- Undercutting

- Intercoat debonding

- Peeling

|  |

|

Coating Materials

- Barrier Coatings

- Epoxy

- Polyurethane

- Alkyds

- Thermal Spray and Galvanizing

|

| |